In today’s highly competitive foodservice industry, an efficient stir fry machine not only saves labor in the kitchen but also boosts order efficiency and ensures consistent food quality. However, with so many options on the market, how can restaurant owners choose the right automatic cooking machine for their needs? The following five key factors (and hidden tips) will help you navigate this decision-making process.

1. Heat Control: Precision and Smart Control are the Soul of "Wok Hei"

Key Challenge: Traditional stoves rely on the chef’s experience, resulting in inconsistent heat levels that make it difficult to recreate the desired “wok hei.”

Buying Tips:

- Smart Temperature Control System: Choose equipment that features high-precision temperature sensors and intelligent algorithms. This system automatically adjusts heat levels and cooking times based on the type, amount, and moisture content of the ingredients, accurately simulating fast stir frying.

- Programmable Multi-Stage Heat Control: The automatic stir fryer machine should support various cooking styles, such as stir-frying, braising, or deep-frying, with adjustable heat levels, rather than relying on a simple constant temperature setting.

2. Flavor Reproduction and Recipe Management: The Foundation of Standardization

Key Challenge: Chef turnover leads to inconsistent flavor, making it hard to maintain quality across multiple locations.

Buying Tips:

- Precise Reproduction Capability: The self cooking machine must execute the chef’s settings (temperature, time, speed, and ingredient order) accurately to ensure the same dish tastes the same every time, even after thousands of repetitions.

- Powerful Recipe Program Library: Choose equipment with large local storage that allows you to save and quickly call up numerous proprietary recipes.

- “Chef Recording” Feature: This feature allows chefs to manually operate the machine, recording all the key parameters and generating a customized program. This simplifies recipe development and standardization.

3. Automation and Ease of Operation: Efficiency and Labor Cost Reduction

Key Challenge: Complex equipment operation and high training costs prevent true labor savings.

Buying Tips:

- True One-Touch Cooking: The automatic cooking machine should offer one-touch cooking, where selecting a recipe triggers the machine to automatically complete the entire cooking process: preheating, ingredient addition (if supported), stir-frying, seasoning (if supported), and finishing the dish.

- User-Friendly Design: The interface should be intuitive and simple (large icons, touchscreen), with a clear operation logic. Ordinary staff should be able to operate the machine without extensive training.

- Automatic Ingredient Dispensing and Cleaning (Bonus Features): High-end models may include automatic liquid seasoning dispensing and self-cleaning functions, reducing the need for manual intervention and boosting efficiency.

4. Output Capacity and Efficiency: The Key to Handling Peak Times

Key Challenge: Slow cooking and insufficient capacity lead to customer loss during peak hours.

Buying Tips:

- Single-Meal Output Capacity: Verify the maximum single-pot capacity of the equipment to ensure it meets your restaurant’s typical portion sizes.

- Unit Time Productivity: Consider the cooking speed (e.g., average time per dish, such as 3-5 minutes) and whether the machine can continuously cook multiple batches.

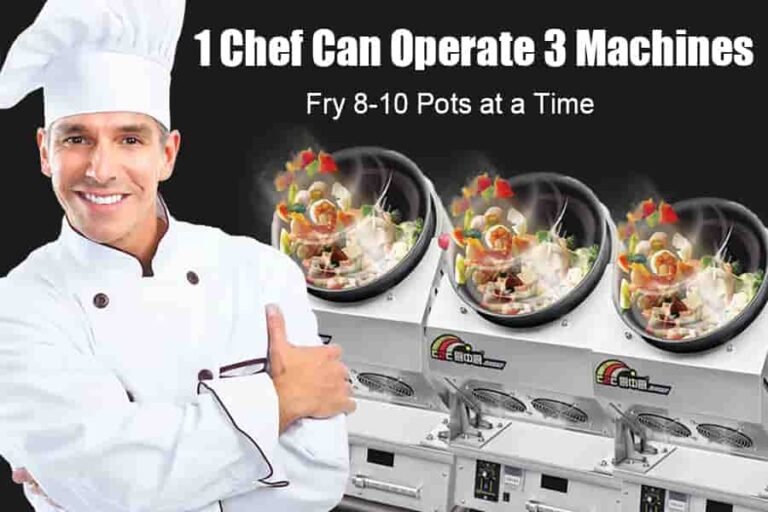

- Labor Efficiency: A high-performance fried rice machine can replace 1-2 wok chefs, significantly reducing labor costs and recruitment pressures.

5. Smart Merchant Management System: A Tool for Digital Management

Device Connectivity and Remote Management: Ensure the machine supports remote monitoring via an app or online dashboard to track status (operating, idle, faulty), control the machine, and perform firmware updates.

Operational Data Analytics: The system should automatically record dish sales, ingredient usage, and equipment utilization. This helps with cost control and schedule optimization.

Inventory Integration (Advanced Feature): The system should integrate with restaurant management software to trigger automatic restock alerts based on sales forecasts or dish preparation.

Hidden Key Point: Reliability – The Foundation of Ongoing Operations

Key Challenge: Frequent equipment failures lead to service disruptions and high maintenance costs.

Buying Tips:

Core Component Quality: Pay attention to the quality and brand of critical components such as motors, heating modules (electromagnetic coils/gas valves), and control boards.

Durability and Material: Ensure that parts in contact with food, like the wok body and stir arms, are made of durable, food-grade stainless steel. The overall structure should be sturdy and reliable.

Heat Dissipation and Protection Design: A good cooling system ensures long-term operation, while protective features (e.g., oil and water splash protection) safeguard electrical components.

After-Sales Service Network: Check if the manufacturer provides local repair services and readily available spare parts. Ensure warranty terms are clear and reasonable.

Wise Selection: Comprehensive Evaluation and On-Site Testing

Choosing a commercial stir fry machine is not just about price comparison. Restaurant owners must analyze their cuisine’s unique needs, peak hour traffic, kitchen space, and requirements for smart management. Use the following approach to assess potential models:

Clarify Core Requirements: Are you looking for superior wok heat (advanced heat control)? Or a standardized solution for chain restaurants (strong recipe management)? Or do you need fast-food efficiency (large capacity + quick cooking)?

See It in Action: Request live demonstrations to try your signature dishes, experience the cooking speed, and assess the quality of the finished dishes.

Consider the Total Ownership Cost: Beyond the initial purchase price, factor in savings on labor costs, increased table turnover, reduced food waste, and potential maintenance costs.

When smart technology meets traditional cooking, an excellent wokmachine has become a necessary tool for modernizing kitchen operations and improving restaurant efficiency. By precisely matching your restaurant’s needs, you can achieve true cost reduction and efficiency, gaining an edge in the competitive market.

-

Planetaire Wok Roerbakpan Kantelbare Kookmachine Automatische Mixer Kookpan met Roerfunctie

Lees meer -

Restaurant Automatische Roerbak Machine Gas Countertop Robot Fried Rice Wok Fryer Robot Cooker te koop

Lees meer -

Automatische Wok Machine Gas / Inductie Countertop roterende Robot Roerbak Cooker Machine te koop

Lees meer -

Auto Cook Wok Machine Gas / Inductie Countertop Robot Zelf Roerende Wok voor Restaurant

Lees meer -

Industriële Gebakken Rijst Maken van Apparatuur Gas / Inductie vrijstaande Automatische roerbakken Machine Spinning Wok voor Verkoop

Lees meer -

Roerbak Machine 1 Branders Gas / Inductie Vrijstaande Wokie Kookmachine Spinnende Wok Fried Rice Cooker Machine te koop

Lees meer -

Automatische Roerbakmachine Enkele Brander Handmatige lift Gas / Inductie Aanrecht Robot Zelf Roerbak Kookmachine voor Commercieel Restaurant, Industrieel, Catering Keuken

Waardering 5.00 uit 5$890.00 Toevoegen aan winkelwagen -

Auto Koken met de Wok Machine Enkele Brander Gas / Inductie vrijstaande Automatische Spinnen Gebakken Rijst Koken in de Wok voor Verkoop

Lees meer